- Language:

🔍Search

- ☏+86 400-0760-826

- ✉lhzb@lianhewl.com

🔍Search

E-mail:lhzb@lianhewl.com

E-mail:lhzb@lianhewl.com Tlephone:+86 400-0760-826

Tlephone:+86 400-0760-826 Landline:+86 18933323098

Landline:+86 18933323098 Fax:0760-88898816

Fax:0760-88898816Industry News

How much do you know about the cognition of smart shelves and automated stereoscopic warehouses?

release time: 2022-03-07Click volume: 132

Enterprises generally need to have a clear understanding and planning of the following factors in the early stage of building an automated three-dimensional warehouse. Once the automated three-dimensional warehouse project is built, it may cost a lot to rebuild.

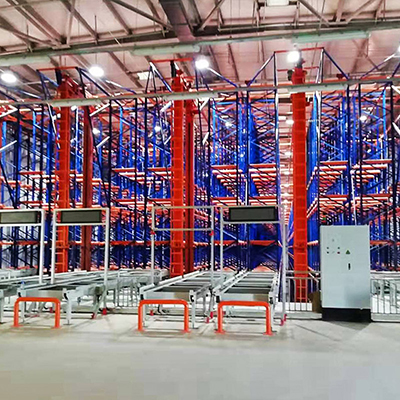

Automated Warehouse

1. System work ability: the ability of the three-dimensional warehouse logistics system (throughput) to store, store and operate;

2. Inventory capacity: the capacity of the three-dimensional warehouse, including the total amount of all items that need to be stored and temporarily stored in the three-dimensional warehouse;

3. Information processing: the ability of three-dimensional warehouse information processing, including information collection, information processing, information query, information communication, and even business information processing capabilities;

4. Peripheral logistics processing: how to unload, inspect, assemble, and transport the goods to the roadway of the high-level shelf, and then disassemble, merge, pick, transport, and load the goods after they are taken out from the high-level shelf;

5. Human-machine connection ability: the connection between the operator and the system, the man-machine interface, the information input, the processing of the inspection unqualified products, the entry into the automatic handling line, etc.;

6. Functional requirements: warehousing, handling, information processing, personnel operation and maintenance, etc.;

7. Boundary conditions: site conditions (length, width, height), power supply, ground foundation, etc.;

8. Requirements for the degree of automation: manual, semi-automatic, fully automatic, etc.;

9. Auxiliary requirements: video surveillance, temperature and humidity measurement and control, access control, manual handling vehicles, etc.;

10. Construction period: It has gone through multiple links such as design, procurement, manufacturing, processing, assembly, control and management of software development, inspection, packaging, transportation, on-site installation, debugging, acceptance and training. The time is too short to guarantee a higher quality;

11. Do not pursue the high performance of a single (species) device too much, but ignore the performance of the overall system

12. Various requirements should be appropriate, and the key is to meet your own use requirements. If the requirements are too low to meet the needs of use, if the requirements are too high, the cost of the system may be too high, the reliability will be reduced, the implementation will be difficult, the maintenance will be inconvenient, or the flexibility will be deteriorated;

13. The daily maintenance of the system is very important. Just like the maintenance of the car, the system should be maintained frequently to keep the system in good working condition, prolong the service life of the system, and discover hidden faults in time;

14. In order to use the automated three-dimensional warehouse well, professional management and maintenance personnel are required.

Latest News

24-hour free consultation

Please enter your contact number, Please add area code to your landline.