- Language:

🔍Search

- ☏+86 400-0760-826

- ✉lhzb@lianhewl.com

🔍Search

E-mail:lhzb@lianhewl.com

E-mail:lhzb@lianhewl.com Tlephone:+86 400-0760-826

Tlephone:+86 400-0760-826 Landline:+86 18933323098

Landline:+86 18933323098 Fax:0760-88898816

Fax:0760-88898816Industry News

What are the production and processing steps of storage rack columns?

release time: 2021-12-24Click volume: 135

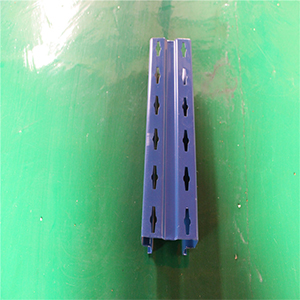

Columns are one of the most important parts of storage shelves and play a vital role. So how is the storage rack column produced? The following editor introduces the production and processing steps of the shelf column.

The raw materials purchased by the shelf manufacturers are all high-quality cold-rolled steel plates produced by well-known domestic steel manufacturers. The width of the cold-rolled steel plates is generally 800-1250 mm. Because there are several external dimensions of the shelf columns, the manufacturers need to cut the purchased raw materials into the desired size. Then cut the cold-rolled steel plate longitudinally and send it to automatic punching using a forklift, and then turn on the punching machine. At present, the commonly used rack column holes are diamond-shaped holes, and the punched column materials are brought to the rolling mill, and the cold-rolled steel is rolled by the rolling mill.

So how to control the length of the shelf column in these processes? This also needs to be carried out synchronously on the rolling mill. Once such a batch of complete racking columns are processed, that is, the racking columns are completed at this step. Since the power supply of the racking columns is on the bottom plate, the columns need to be welded to the ground. After such a series of processes, the treatment of a shelf column has been basically completed, and finally the surface treatment process. The shelf surface treatment generally requires dephosphorization, rust removal, pickling, dephosphorization, spraying, etc.

Latest News

24-hour free consultation

Please enter your contact number, Please add area code to your landline.